Leave Your Message

In today's fast-paced world, maintaining hygiene is a top priority. A reliable Sterilizer For Cassettes is essential for dental practices and laboratories. These devices ensure that instruments are disinfected properly, preventing cross-contamination.

Choosing the right sterilizer can be challenging. There are various models available, each with unique features and benefits. Factors like size, speed, and efficacy play a crucial role in selection. Some options might lack sufficient drying capabilities, which can be problematic.

Understanding your specific needs is key to making an informed choice. You may find that a less expensive sterilizer offers basic functions but lacks advanced features. This could lead to frustration down the line. In this article, we will explore the top five Sterilizer For Cassettes options available. Get ready to discover the right fit for your requirements.

Sterilizers for cassettes play a vital role in the health and dental industries. These devices are designed to eliminate harmful microorganisms that can reside on instruments. According to a report by the Centers for Disease Control and Prevention (CDC), improper sterilization can lead to the spread of infections, potentially affecting thousands of patients. This statistic highlights the critical need for effective sterilization processes.

Inadequate sterilization can result in significant risks. Research indicates that nearly 1 in 100,000 patients may contract an infection due to improperly sterilized equipment. Therefore, using reliable sterilizers is essential. Many professionals overlook the importance of routine checks and maintenance of these devices. In a fast-paced environment, it's easy to neglect the specifics, leading to compromised safety.

The development of sterilizers has evolved. Advanced technologies are now available to minimize human error. However, some clinics still rely on outdated systems. This can lead to dangerous outcomes. Awareness and proper training on the use of sterilizers are crucial. Ultimately, prioritizing sterilization can safeguard patient health and ensure overall hygiene standards are met.

| Model | Type | Capacity | Cycle Time | Features |

|---|---|---|---|---|

| Model A | Class B | 8 cassettes | 30 minutes | Automatic, Compact design |

| Model B | Class N | 5 cassettes | 25 minutes | User-friendly Interface, Efficient |

| Model C | Class B | 10 cassettes | 40 minutes | Advanced Controls, Digital Display |

| Model D | Class N | 7 cassettes | 35 minutes | Portable, Quick Start |

| Model E | Class B | 12 cassettes | 50 minutes | High Capacity, Energy Efficient |

When it comes to sterilizing cassettes, several types of sterilizers are frequently used. Autoclaves are among the most common choices. They use steam under pressure to eliminate all forms of bacteria and viruses. The process is efficient and usually takes less time than other methods. However, ensuring the right temperature and pressure is crucial. Otherwise, some microorganisms may survive.

Dry heat sterilizers are another option. They work by circulating hot air around the cassettes. This method is effective, but it can take longer to achieve sterilization. Many professionals find it less reliable because it requires precise timing. Improper use can lead to inadequate sterilization.

Chemical sterilizers are also prevalent. They use chemical agents to disinfect cassettes. This approach is often suitable for heat-sensitive materials. The downside? The lingering smell and potential chemical residues can be concerning. Users must also ensure they follow proper protocols to avoid contamination. Each type has its pros and cons, and the choice should be made carefully.

When selecting a cassette sterilizer, several key features should be considered. First, the sterilization cycle time matters. Quick cycles can improve workflow in busy environments. Reports show that efficient sterilizers can cut cycle times to below 30 minutes. This is crucial for maintaining a steady supply of sterilized instruments.

Temperature control is another vital feature. Precise temperature regulation ensures effective sterilization. A study indicated that deviations in temperature could lead to insufficient microbial kill rates. Thus, a reliable sterilizer should have consistent temperature settings.

Moreover, the sterilizer’s capacity is important. Clinics often work with a limited number of cassettes at a time. A device that holds a higher number of cassettes will enhance productivity. Efficiency can be compromised if the unit does not fit enough items.

Noise level is often overlooked but can impact staff satisfaction. Some sterilizers operate quietly, while others can be disruptive. Understanding these nuances can greatly influence the choice of equipment. Addressing these factors can result in both operational efficiency and a more comfortable working environment.

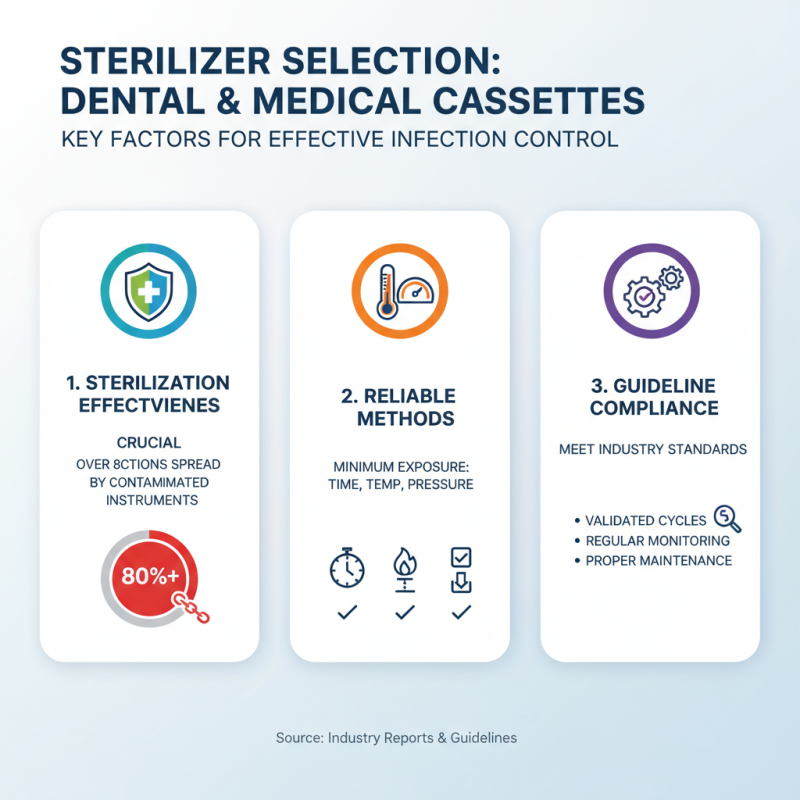

When choosing sterilizers for dental and medical cassettes, several factors come into play. The effectiveness of sterilization is crucial. According to industry reports, over 80% of infections can spread through contaminated instruments. This highlights the need for reliable sterilization methods. Most guidelines recommend minimum exposure times, temperature, and pressure levels for sterilizers.

For instance, steam sterilizers should reach at least 121°C for 15 minutes to ensure efficacy. Additionally, it's essential to consider the ease of integration into existing workflows. Complicated procedures can lead to user errors. Training staff on proper sterilization techniques is often overlooked. Many facilities report that a lack of training can impact sterilization outcomes.

Another consideration is the maintenance of these devices. Regular servicing is key to ensure ongoing performance. Unfortunately, many practices neglect this aspect. Some sterilizers may show signs of wear, which can compromise the sterilization cycle. It's vital to have a clear maintenance schedule. The decision on which sterilizer to use involves weighing these aspects carefully. Balancing cost, effectiveness, and workflow efficiency can prove challenging.

Using cassette sterilizers can ensure cleanliness in various settings. However, using them effectively requires attention to detail. Regularly check the device for any signs of wear. Incomplete sterilization can lead to contamination. Always follow the manufacturer's instructions for loading. Overloading the sterilizer is a common mistake. Items need space to allow steam or gas to circulate.

Routine maintenance is necessary for optimal performance. Clean the sterilizer regularly to prevent buildup. Residue can affect efficacy over time. Additionally, keep an eye on the expiration dates of sterilization materials. Outdated materials may not provide the desired results. Remember to document each sterilization cycle. Mistakes happen, and recording helps identify issues in processes.

Education is key. Proper training on how to use these sterilizers effectively minimizes potential risks. Sometimes, staff may overlook simple steps. Emphasizing the importance of each step can improve overall safety. Evaluating procedures regularly can also uncover hidden issues. A proactive approach helps maintain high standards. Continually seek improvements for better sterilization outcomes.