Leave Your Message

In the field of water quality analysis, the importance of accurate measurements cannot be overstated. One essential instrument for gauging the ionic content and overall electrical conductivity of liquids is the Digital Conductivity Meter. This versatile device plays a crucial role in various industries, including agriculture, aquaculture, and environmental monitoring, enabling users to obtain precise readings that inform crucial decisions. Understanding how to operate this tool effectively is paramount to ensuring the reliability of the data collected.

Utilizing a Digital Conductivity Meter effectively demands a balance of proper technique and knowledge. From calibration procedures to maintenance tips, every aspect contributes to obtaining accurate and consistent measurements. This guide aims to present practical advice that will not only enhance your proficiency with the meter but also elevate the quality of your findings. By mastering the use of the Digital Conductivity Meter, users can improve their analytical capabilities, leading to informed decisions that can positively impact their projects and research.

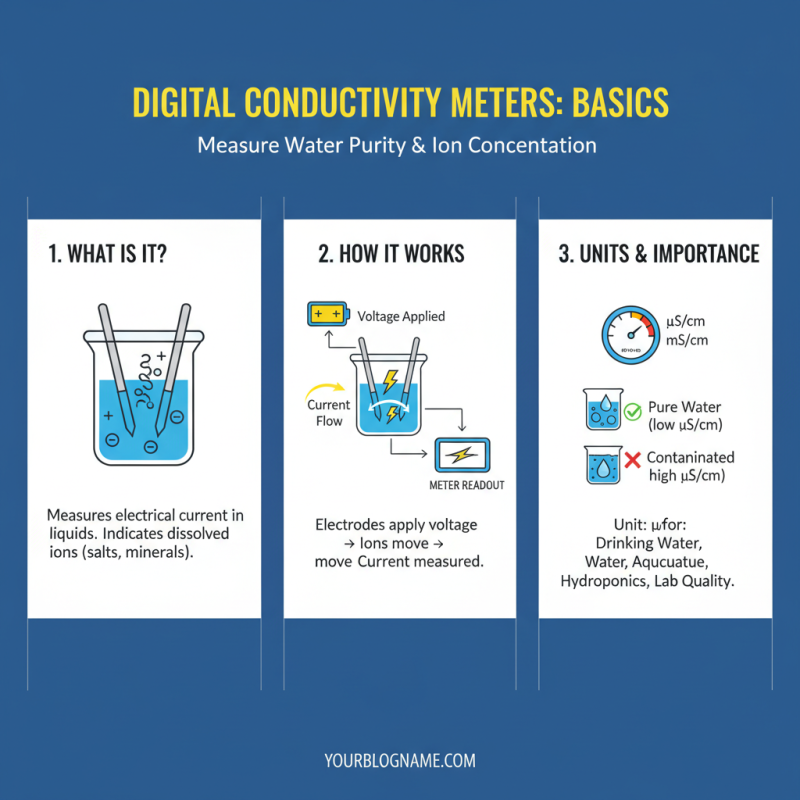

Digital conductivity meters are essential tools for measuring the electrical conductivity of liquids, which serves as an indicator of the concentration of ions present in the solution. Understanding the basics of these meters is crucial for effective operation. At the core, conductivity is the ability of a solution to conduct electricity, which depends on the number of charged particles (ions) in the water. Digital meters use electrodes that are immersed in the solution; the meter then applies a voltage between these electrodes, measuring the current that flows through the liquid. This measurement is converted into conductivity readings, typically expressed in microsiemens per centimeter (µS/cm).

To use a digital conductivity meter effectively, it is important to calibrate the device regularly to ensure accurate readings. Calibration typically involves using standard solutions with known conductivity to adjust the meter's settings. Additionally, proper electrode maintenance is crucial, as dirty or damaged electrodes can lead to erroneous measurements. Users should also be aware of factors that can influence readings, such as temperature, which often necessitates temperature compensation for the most accurate results. Familiarity with the operational manual can provide essential tips for troubleshooting common issues and understanding the display readings.

When choosing the right digital conductivity meter, the first step is to consider the specific applications for which you intend to use the device. Different fields, such as agriculture, aquaculture, or laboratory research, have varying requirements for conductivity measurements. For instance, if you are measuring water quality in a fishery, you may need a meter capable of providing accurate readings in low-conductivity ranges, while a laboratory might focus on meters that offer advanced features like temperature compensation and data logging capabilities.

Another crucial factor is the range and accuracy of the meter. Ensure that the device you select can measure conductivity levels relevant to your work. Look for meters with a wide measurement range and high precision to guarantee reliable results. Additionally, consider features like ease of calibration, display readability, and whether the device is portable or intended for stationary use. Having a meter that fits comfortably in your environment and provides clear readings will enhance the effectiveness of your measurements, making it easier to make informed decisions based on the data you gather.

To ensure accurate readings from your digital conductivity meter, proper calibration is essential. Start by assembling your equipment: make sure you have the meter, a clean container for the calibration liquids, and the standard solutions with known conductivity values. It’s advisable to use solutions that closely match the range of conductivity you typically measure. Pour the appropriate amount of standard solution into the clean container, making sure it's enough to submerge the probe without any interference.

Next, turn on your conductivity meter and allow it to stabilize. Immerse the probe in the standard solution, ensuring that it is fully submerged but not touching the bottom or sides of the container. Follow the specific instructions of your meter for calibration mode selection. Many devices have a straightforward calibration process, requiring you to either input the standard value manually or confirm if the reading matches the known value. If necessary, adjust the calibration until the meter accurately reflects the solution's conductivity. Repeat this process with additional standards, especially if you work with a wide range of conductivity levels, to enhance precision in your measurements and ensure reliable results in your analyses.

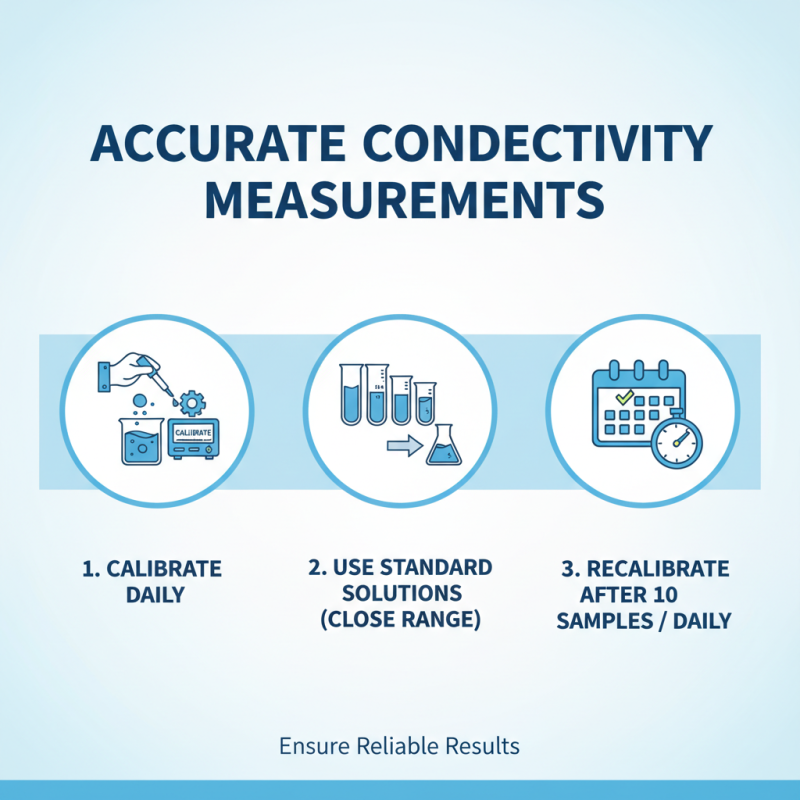

When taking conductivity measurements, ensuring accuracy is paramount. First, it's essential to calibrate the digital conductivity meter before each use. Calibration should be done using standard solutions that are close in range to the samples being tested. This ensures that the readings are reliable and can be compared across different measurements. It’s recommended to conduct calibration at least every day or after every 10 samples to account for any potential drift in the meter’s reading.

Another critical aspect is to maintain proper sample handling techniques. Samples should be well mixed and free from bubbles or large particles that could interfere with the reading. Make sure to immerse the electrode of the meter fully in the sample to the appropriate depth to avoid inaccurate readings, as insufficient immersion can lead to skewed results. Also, allow the meter to equilibrate for a moment to stabilize the reading before recording the measurement. By following these best practices, users can ensure precise and consistent conductivity measurements, facilitating reliable data collection in their experiments or processes.

When it comes to maintaining the longevity of your digital conductivity meter, regular care and attention are paramount. A study by the American Society for Testing and Materials (ASTM) indicates that improper maintenance can lead to a decrease in meter performance, with accuracy diminishing by as much as 15% after prolonged use without proper cleaning and calibration. Ensuring that the electrodes and the probe are clean and free from contaminants is essential. Regularly rinsing the probe with distilled water and using appropriate cleaning solutions can significantly extend its lifecycle. Moreover, calibration should be performed routinely according to manufacturer guidelines, as failing to do so can lead to erroneous readings, which should be avoided in critical tasks such as water quality testing.

Temperature and storage conditions also play a crucial role in the durability of conductivity meters. According to the International Society of Automation, exposure to extreme temperatures and humidity can adversely affect the internal components of the device. Ideally, conductivity meters should be stored in a controlled environment when not in use, ideally in a protective case. The use of silica gel packs can help maintain moisture levels. Additionally, devices should be periodically checked for signs of wear or damage, as proactive measures taken at early signs can prevent costly repairs or replacements later on. Such routine preventative maintenance not only preserves accuracy but also enhances the overall integrity and reliability of the measurement tool over time.

| Tip | Description | Frequency | Notes |

|---|---|---|---|

| Calibration | Regularly calibrate the meter to ensure accurate readings. | Monthly | Use standard solutions for calibration. |

| Cleaning | Clean the electrode after each use to prevent contamination. | After each use | Use a soft cloth and appropriate cleaning solution. |

| Storage | Store the meter in a protective casing to avoid damage. | Always | Avoid extreme temperatures and humidity. |

| Battery Maintenance | Check the battery regularly and replace if low. | Every 6 months | Use high-quality batteries for better performance. |

| Software Updates | Keep the device software up to date for improved functionality. | As available | Check the manufacturer's website regularly. |