Leave Your Message

When it comes to choosing the right Ultrasonic Cleaning Tank for your needs, the decision can be daunting due to the myriad of options available in the market today. Industry expert Dr. Emily Carter, a leading figure in ultrasonic cleaning technology, emphasizes, “Finding the perfect ultrasonic cleaner is not just about size; it's about understanding your specific cleaning requirements and application.” This statement encapsulates the essence of selecting an Ultrasonic Cleaning Tank, as it requires a thorough analysis of the items to be cleaned, the cleaning solution used, and the desired outcome.

An Ultrasonic Cleaning Tank operates by using high-frequency sound waves to agitate a fluid, creating millions of tiny bubbles that effectively remove dirt, grime, and contaminants from surfaces. However, the effectiveness of this cleaning method hinges on the right selection of tank size, power, and frequency. Whether you're a jeweler seeking to restore the shine of intricate pieces or a laboratory professional needing precision cleaning for delicate instruments, understanding the specifications and features can greatly enhance cleaning efficiency and effectiveness.

Ultimately, investing time in research and consultation can lead you to an Ultrasonic Cleaning Tank that not only meets your cleaning demands but also optimizes the cleaning process, ensuring a high-quality outcome. As you embark on this journey, remember that the right choice can yield significant long-term benefits for your cleaning tasks.

Ultrasonic cleaning technology utilizes high-frequency sound waves to create microscopic bubbles in a cleaning solution. When these bubbles implode, they generate powerful cleaning action that penetrates crevices and removes contaminants from the surface of various materials. This method is particularly effective for delicate items such as jewelry, medical instruments, and electronic components, where traditional cleaning methods may cause damage. Understanding the fundamentals of ultrasonic cleaning can help you assess its suitability for your specific applications, ensuring that you achieve optimal results.

When choosing an ultrasonic cleaning tank, consider the materials you will be cleaning and the types of contaminants you want to remove. For items with intricate designs or hidden areas, a tank with adequate frequency can deliver superior cleaning power without causing damage. Additionally, the size of the cleaning tank is vital; ensure that it is sufficient to accommodate the largest items you plan to clean while allowing for effective cleaning flow.

Tips: Before making a decision, it's beneficial to test the cleaning process on a small item to gauge the tank's effectiveness. Also, pay attention to the cleaning solution's compatibility with the materials being cleaned to avoid any adverse reactions. Regular maintenance of the ultrasonic cleaner will help maintain performance and prolong the lifespan of the equipment.

| Feature | Description | Application |

|---|---|---|

| Tank Size | Determines the volume of items that can be cleaned simultaneously. | Industrial parts cleaning, Jewelry cleaning |

| Frequency | Influences cleaning effectiveness, typically between 20 kHz to 40 kHz. | Delicate items, Heavy-duty cleaning |

| Heating Capability | Enhances cleaning performance by using heated solutions. | Medical instruments, Electronics |

| Cleaning Solutions | Chemical solutions used to enhance ultrasonic cleaning. | Automotive parts, Optical components |

| Durability | Resistance to corrosion and wear, essential for long-term use. | Heavy Manufacturing, Precision Cleaning |

| Portability | Weight and design affecting ease of transport. | Fieldwork, Mobile cleaning applications |

When selecting the right ultrasonic cleaning tank, it's essential to evaluate your specific cleaning needs and requirements. Consider the types of items you intend to clean, as different materials and contaminants may necessitate varying cleaning frequencies and power levels. For instance, a recent industry report revealed that 30% of users found that adjusting frequency helped achieve better cleaning results for intricate items like jewelry and medical instruments. Additionally, understanding the volume of items you plan to clean at once is crucial, as larger tanks can handle more significant batches efficiently, thereby saving time and labor.

Tips: When assessing your cleaning needs, make a list of the materials and contaminants you will encounter. This will help you determine the optimal frequency and tank size. Moreover, examine the tank's heating capabilities, as elevated temperatures can enhance cleaning effectiveness, particularly for heavily soiled components.

Another vital aspect is the maintenance requirements of the ultrasonic cleaner. Regular maintenance can prolong the lifespan and performance of the tank. Statistics from the cleaning industry indicate that ultrasonic tanks with routine maintenance can last up to 50% longer than those that are neglected. Therefore, consider selecting a model that not only meets your current cleaning requirements but can also adapt to future needs, ensuring versatility and longevity.

This bar chart illustrates the average specifications for ultrasonic cleaning tanks based on key features: volume, frequency, power, heating capability, and price. These factors play a significant role in helping you choose the right ultrasonic cleaning tank for your specific requirements.

When selecting the right ultrasonic cleaning tank, several critical factors should be considered to ensure it meets your specific cleaning needs.

First, the tank's size is crucial; it should be large enough to accommodate the items you intend to clean without crowding.

According to a report by the Ultrasonic Cleaning Association, a properly sized tank can enhance cleaning efficiency by up to 20%, compared to smaller, overcrowded units.

Another essential factor is the frequency of the ultrasonic waves produced by the tank.

Lower frequencies (20 kHz to 40 kHz) are effective for heavy-duty cleaning, making them suitable for items with tougher residues, while higher frequencies (above 40 kHz) provide a gentler cleaning action, ideal for delicate parts.

Research shows that selecting the appropriate frequency can significantly reduce the risk of damage to sensitive components.

Tips: Always assess your cleaning solution's compatibility with the ultrasonic tank to avoid chemical degradation.

Experimenting with different temperature settings can also optimize cleaning performance, as higher temperatures generally enhance cleaning action in ultrasonic baths.

When selecting an ultrasonic cleaning tank, understanding the various types and sizes available is crucial to meet your specific cleaning needs. Ultrasonic cleaning tanks come in a range of capacities, typically varying from 0.5 liters for smaller, handheld devices to industrial-sized units exceeding 100 liters. According to industry reports, larger tanks not only accommodate bulkier items, but they also enhance the efficiency of cleaning larger batches simultaneously, making them ideal for high-volume operations such as automotive or industrial cleaning.

In terms of technology, ultrasonic tanks can differ significantly in frequency and power output. Standard frequencies range between 20 kHz to 40 kHz, with lower frequencies providing more aggressive cleaning action, suitable for heavier contaminants. Conversely, higher frequencies are preferred for more delicate items, as they produce finer cavitation bubbles, reducing the risk of damage. A study by the American Cleaning Institute indicates that higher frequency systems can achieve 20% more effective cleaning for intricate components when compared to their lower frequency counterparts.

Size considerations are equally important; the dimensions of the items to be cleaned will dictate the required tank size to ensure thorough cleaning. Tanks that are too small may lead to inefficient cleaning results, as items might not receive uniform exposure to the ultrasonic waves. Additionally, reports suggest that users often overlook the importance of tank depth – a deeper tank can improve the cleaning process by allowing for better wave propagation and ensuring that larger items are fully submerged. Therefore, evaluating both the size and type of ultrasonic cleaning tank is essential for optimal performance and effective cleaning results.

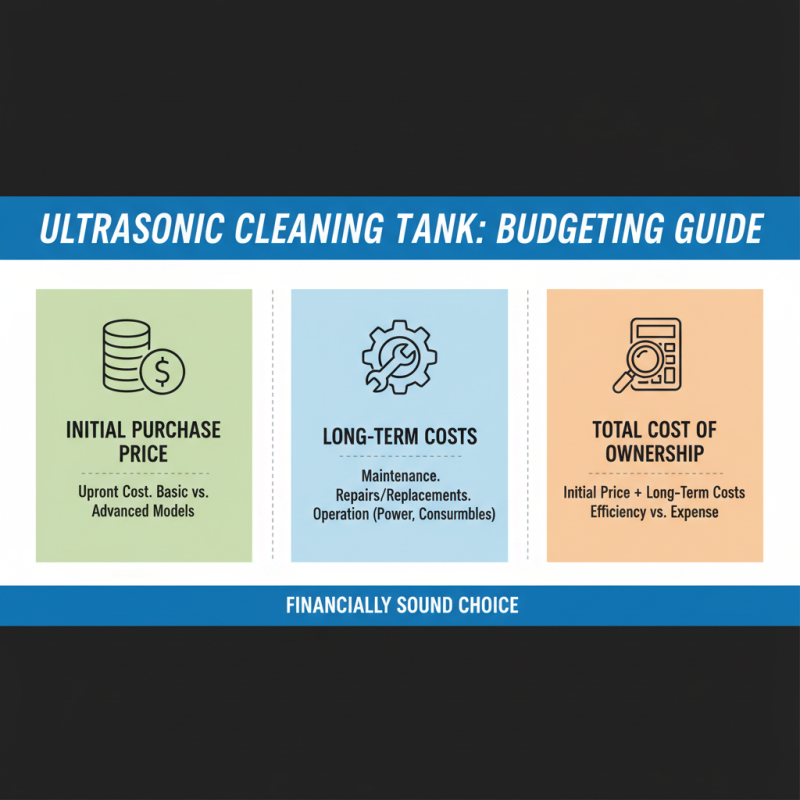

When selecting an ultrasonic cleaning tank, budget considerations play a crucial role in the decision-making process. It's essential to establish a clear budget that not only considers the initial purchase price but also the long-term costs associated with maintenance and operation. A higher upfront investment might yield advanced features, such as customizable settings and larger capacities, which can improve efficiency and effectiveness. Conversely, a lower-priced model may require more frequent repairs or replacements, thus increasing overall expenses. Evaluating the total cost of ownership can help ensure that you make a financially sound choice.

Maintenance tips for your ultrasonic cleaning tank are equally important to ensure longevity and optimal performance. Regularly check and clean the tank, as residue and contaminants can affect the ultrasonic waves and reduce cleaning effectiveness. Additionally, ensure the transducers and heating elements are functioning correctly; this may involve visual inspections and periodic professional servicing. Always use the appropriate cleaning solutions specific to your cleaning needs, as using incompatible substances can damage the tank and compromise its efficiency. Regular maintenance, combined with wise budgeting, will ensure that your ultrasonic cleaning tank meets your needs effectively over time.