Leave Your Message

Choosing the right Ultrasonic Cleaning Tank can seem overwhelming. There are many options available, each with different features. It’s essential to understand your specific needs before making a decision.

Think about the items you will clean. Jewelry, small parts, or delicate instruments all require different setups. The size of the tank matters too. You don’t want a tank too small for your items. This may lead to uneven cleaning and frustration.

Another aspect to consider is the frequency of use. Occasional use might not justify a high-end model. However, if you clean regularly, investing in a reliable Ultrasonic Cleaning Tank becomes crucial. Pay attention to the power, capacity, and frequency settings. These details can make a significant difference in performance. Reflect on what matters most for your cleaning tasks.

When selecting an ultrasonic cleaning tank, several factors come into play. The size of the tank is crucial. Consider the items you wish to clean. A larger tank accommodates bigger items but may use more energy. If your items are small, a compact tank could suffice.

The frequency of the ultrasonic waves matters too. Common frequencies are 28 kHz and 40 kHz. A lower frequency is better for heavy-duty cleaning. Higher frequencies work well for delicate items. Assess what materials you'll clean to choose the right frequency.

**Tip:** Always check the tank's material. Stainless steel is durable and resistant to corrosion. This can affect the tank's lifespan and cleaning efficiency.

Consider your budget as well. More expensive doesn’t always mean better. Research and compare features. Look at additional functions, like heating or timers.

**Tip:** Sometimes a basic model meets all your needs. Avoid overspending on unnecessary features. Focus on what truly makes sense for you.

Reflecting on these factors helps in making a smarter purchase. An informed choice leads to better results in your cleaning tasks.

| Factor | Description | Recommended Value |

|---|---|---|

| Tank Size | The internal dimensions of the cleaning tank, which determine the capacity. | 1 to 100 liters |

| Frequency | Operating frequency that influences cleaning effectiveness. | 28 kHz to 40 kHz |

| Heating Function | Indicates whether the tank can heat the solution, aiding in cleaning. | Yes |

| Power Rating | The energy consumption of the tank, affecting cleaning speed. | 50 W to 600 W |

| Timer | The ability to set a specific cleaning duration. | 0 to 60 minutes |

| Cleaning Solution Compatibility | Suitability of the cleaning tank for various chemicals. | Water, degreasers, and specialized cleaners |

| Portability | Ease of movement and storage of the ultrasonic tank. | Lightweight designs |

| Material | Material of the tank impacting durability and chemical resistance. | Stainless steel |

Ultrasonic cleaning frequencies play a crucial role in determining the effectiveness of a cleaning process. Generally, frequencies range from 20 kHz to 400 kHz. Lower frequencies, like 25 kHz, are more effective for heavy-duty cleaning. They create larger cavitation bubbles that implode with greater force. This is ideal for removing stubborn dirt and grime. However, for delicate items, a higher frequency, around 40 kHz, is more suitable. It offers gentler cleaning, reducing the risk of damage.

Tips: When selecting a frequency, consider the materials you'll clean. Metals and plastics can withstand lower frequencies, while delicate glass or jewelry requires higher frequencies. Understand the specific needs of your items before deciding.

A report from the Clean Industry Journal highlights that many users underestimate frequency's impact. Using the wrong frequency can lead to incomplete cleaning. Moreover, it can cause damage to sensitive components. Understanding the appropriate frequency can enhance cleaning performance while protecting your items.

Tips: Test with different frequencies on small areas first. Monitor the results closely. This trial approach may save you from costly mistakes. Remember that optimal cleaning results depend on matching frequency to material type and level of contamination.

Choosing the right ultrasonic cleaning tank is essential. One critical factor is tank capacity. Different applications require different sizes. A small tank might suit light cleaning tasks. However, larger items need more space.

Consider what you will clean. Jewelry, automotive parts, and medical instruments all have varying sizes. If you often clean larger items, a bigger tank is necessary. A small tank may lead to overcrowding, reducing cleaning effectiveness. It may force you to clean in batches, wasting time.

Think about future needs too. Will you expand your cleaning tasks? If yes, choose a larger tank. Otherwise, you could end up with a tank that doesn't meet your needs. Reflect on your current and future requirements. Finding the right balance in tank capacity is vital for efficiency.

This chart illustrates the number of items that can typically be cleaned based on the capacity of ultrasonic cleaning tanks. Selecting a tank that matches your specific cleaning needs is essential for efficiency.

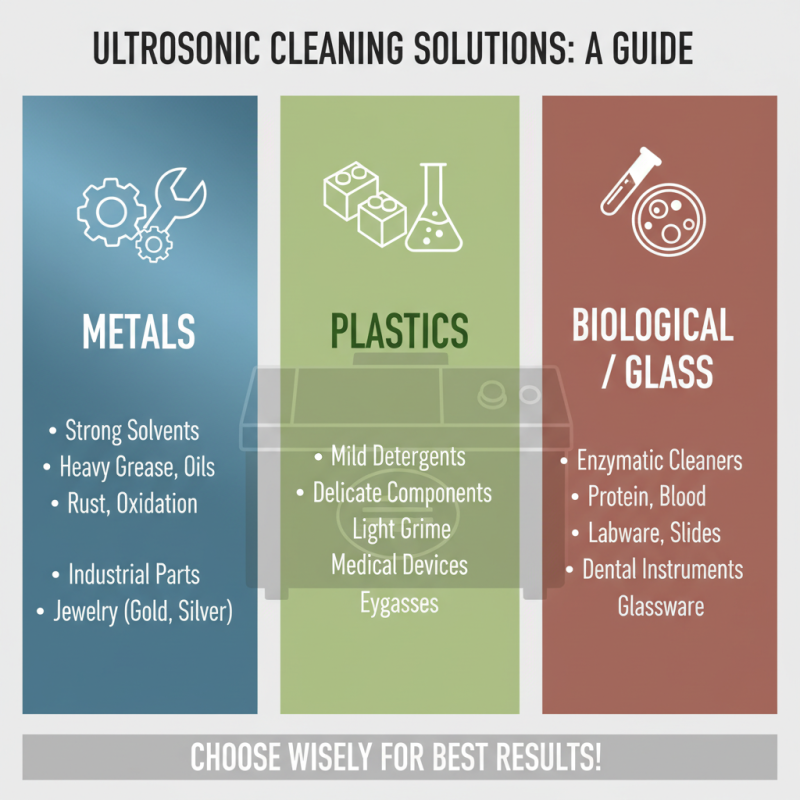

Choosing the right ultrasonic cleaning solution can make a big difference. Different solutions work well for various materials. For example, metals might need a stronger solvent than plastics. The effectiveness of a solution often depends on the type of contaminants involved. Grease, grime, and biological materials all require their specific formulations.

It's essential to consider the concentration of the solution. A higher concentration may seem better, but it can also lead to damage. Balancing strength and safety is crucial. Keep in mind that some solutions might not be compatible with all cleaning tanks. Testing solutions on a small area can help avoid mistakes.

Also, the duration of cleaning matters. Some solutions take longer to work effectively. Users often underestimate this time and end up with less than ideal results. Factors like temperature and agitation can also impact cleaning efficiency. Experimentation might lead to better outcomes. Evaluating these elements carefully can refine your cleaning process over time.

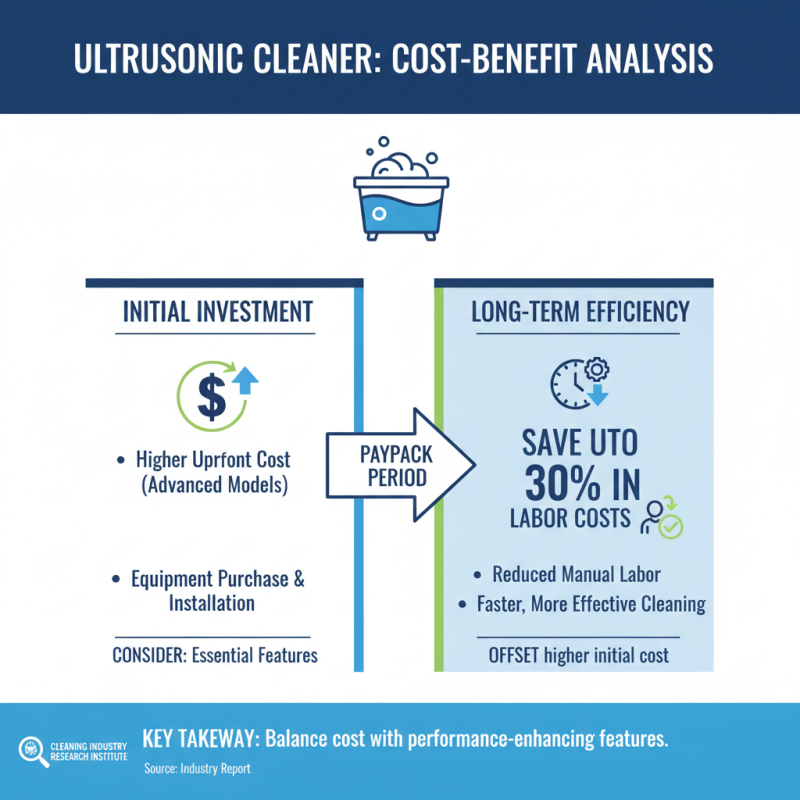

When selecting an ultrasonic cleaning tank, a cost-benefit analysis is essential. Consider the initial investment versus long-term efficiency. A report by the Cleaning Industry Research Institute indicates that efficient ultrasonic cleaners can save up to 30% in labor costs. This can offset the higher upfront cost of more advanced models. Look for features that enhance performance without unnecessary frills.

Different models vary significantly in pricing and functionality. Basic tanks may start at $100, while high-capacity units can exceed $1,000. Evaluate what features matter most for your tasks. Do you need a large capacity or specific frequency settings? Instead of paying for features you won’t use, focus on core requirements.

Maintenance costs also factor in. Some tanks require regular part replacements, which can increase overall expenses. Reviews often overlook this aspect. You may save on purchase but spend more over time. Weigh these elements carefully before deciding. The ideal choice balances price, functionality, and long-term upkeep.