Leave Your Message

Choosing the right Ultrasonic Cleaning Tank is critical for achieving optimal cleaning results across various applications, from industrial maintenance to delicate jewelry restoration. In recent years, the demand for ultrasonic cleaning systems has surged, with the market projected to reach $1.3 billion by 2027, growing at a compound annual growth rate (CAGR) of 6.5% from 2020. This growth is fueled by the increasing need for efficient and environmentally friendly cleaning solutions in diverse sectors such as medical, automotive, and electronics, where precision and effectiveness are paramount.

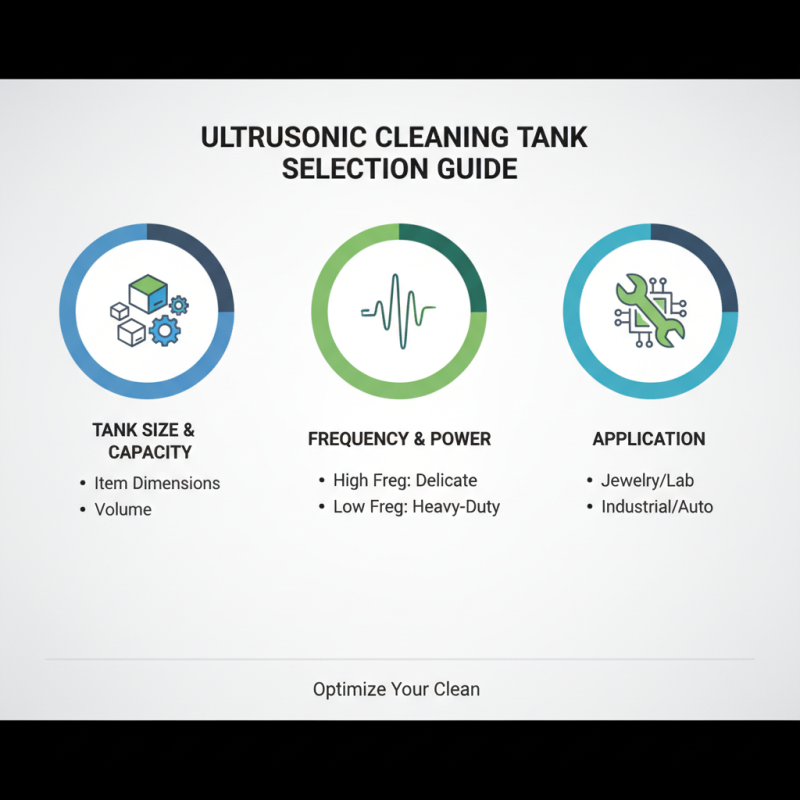

When selecting an Ultrasonic Cleaning Tank, factors such as tank size, frequency, and power must be carefully considered. Reports indicate that higher frequency units, typically ranging from 25 kHz to 130 kHz, are more effective in cleaning delicate items, while lower frequencies are better suited for heavy-duty applications involving larger components. Furthermore, the design and materials of the tank impact its durability and efficiency, which are essential in maintaining consistent cleaning performance. Understanding these parameters is essential for both professionals and DIY enthusiasts who aim to invest in a solution that meets their specific cleaning needs efficiently.

When selecting an ultrasonic cleaning tank, several key factors should be taken into consideration to ensure the best fit for your specific needs. One of the primary considerations is the tank size and capacity, which should correspond with the items you intend to clean. Assess the dimensions and volume of the objects to determine whether a smaller or larger tank will be appropriate. Additionally, consider the frequency and power of the ultrasonic waves; higher frequencies can provide finer cleaning for delicate items, while lower frequencies are often better suited for heavy-duty applications.

Another important aspect is the material and build quality of the tank. Look for corrosion-resistant materials that can withstand prolonged exposure to cleaning solutions without deteriorating. The design of the tank should also facilitate easy loading and unloading, taking into account whether it features a removable basket or other tool for handling items safely. Finally, evaluate the control features available, such as timers and temperature settings, which can enhance cleaning efficiency and achieve optimal results for various applications.

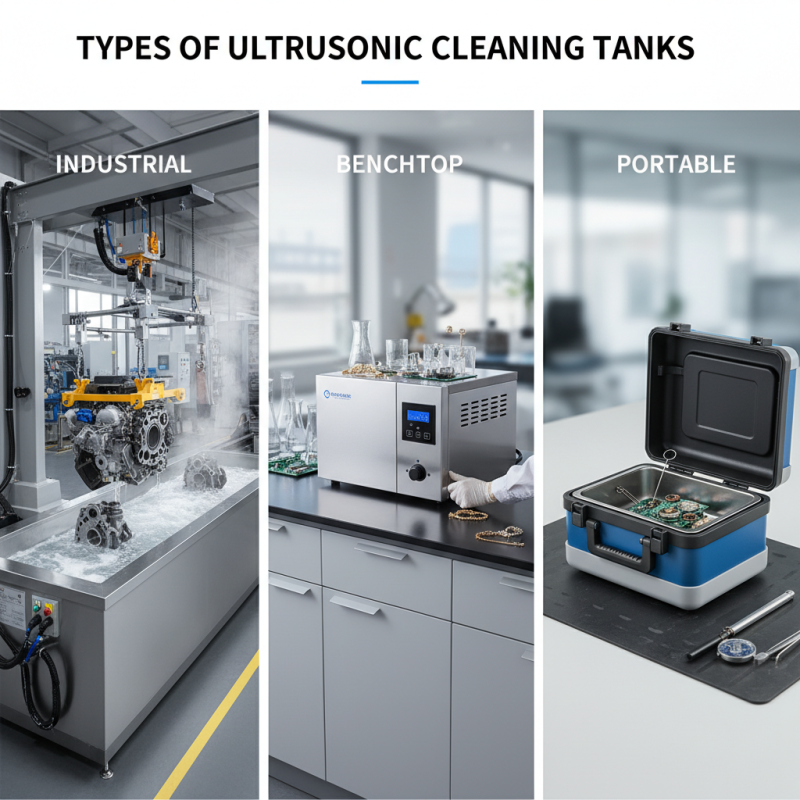

When selecting an ultrasonic cleaning tank, understanding the different types available is crucial for meeting specific cleaning needs. Ultrasonic cleaning tanks can be categorized primarily into industrial, benchtop, and portable models. Industrial ultrasonic cleaners are designed for high-volume applications, offering large capacities that can handle extensive cleaning demands. According to a report by the Global Ultrasonic Cleaning Market, the industrial segment is expected to grow significantly, driven by the increasing adoption across various sectors such as automotive and manufacturing.

Benchtop units are ideal for smaller operations, suitable for labs and workshops that require precision cleaning without the footprint of an industrial machine. These tanks typically feature adjustable frequency settings, which allow users to tailor the cleaning process to different materials and contaminants. A study from the Cleaning Industry Research Institute suggests that benchtop models have gained popularity due to their ease of use and efficiency, especially in delicate cleaning tasks such as jewelry and electronics.

Portable ultrasonic cleaning tanks are gaining traction as they offer flexibility and convenience, enabling users to clean items on-site or in various locations. Their compact design and adaptability make them perfect for small businesses and personal use. A survey by the Ultrasonic Cleaning Association revealed a growing interest in portable models, indicating a shift towards versatile solutions that cater to diverse cleaning environments and needs. Understanding these different types can help users make an informed decision that aligns with their specific requirements and operational constraints.

When selecting an ultrasonic cleaning tank, it's essential to consider the frequency and power ratings, as these parameters significantly influence cleaning effectiveness and application suitability. Ultrasonic cleaners typically operate within a frequency range of 20 kHz to 40 kHz. Lower frequencies (20-30 kHz) provide more vigorous cleaning action, making them ideal for removing heavy contaminants from robust surfaces. Conversely, frequencies above 30 kHz offer gentler cleaning, which is better suited for delicate items that may be damaged by intense agitation. According to a report from the Industrial Cleaning Association, optimal cleaning results are achieved when the frequency aligns with the nature of the items being cleaned.

In addition to frequency, power ratings also play a critical role in ultrasonic cleaning performance. The power of an ultrasonic unit is generally measured in watts, with higher wattage correlating to more powerful cleaning capabilities. A power level of 50 watts per liter is often cited as an effective standard for general cleaning applications, but different cleaning tasks may require adjustments. For instance, intricate assemblies or components with fine details may benefit from lower power settings combined with higher frequencies to prevent damage. Research published in the Journal of Ultrasonic Technology has shown that a well-matched relationship between power and frequency can enhance cavitation activity, resulting in improved cleaning results and efficiency. Understanding these essentials will guide you in selecting an ultrasonic cleaning tank tailored to your specific cleaning needs, ensuring optimal performance and satisfaction.

Choosing the right size and capacity for your ultrasonic cleaning tank is crucial to ensure optimal cleaning results. When assessing your needs, consider the type and quantity of items you plan to clean. Smaller tanks may be suitable for jewelry or small electronic components, while larger tanks are ideal for automotive parts or industrial machinery. Always measure your largest items to ensure they can fit comfortably within the tank, allowing for effective ultrasonic action.

When it comes to capacity, another key factor is the volume of items you need to clean at one time. It’s often more efficient to clean multiple items in one cycle rather than running several smaller batches. A larger capacity tank can save time and energy, but it’s important to avoid overcrowding. Ensure enough space for the cleaning solution to circulate freely, promoting even cleaning. Always refer to the manufacturer's guidelines regarding load limits to maintain the efficiency of the ultrasonic cleaning process.

Remember to think about the frequency of use. If you plan to use the ultrasonic cleaner regularly, investing in a slightly larger model can be beneficial in the long run, accommodating diverse cleaning needs as they arise. By carefully evaluating these factors, you’ll be well on your way to selecting the perfect ultrasonic cleaning tank for your applications.

Ultrasonic cleaning tanks are versatile tools used across various industries due to their effectiveness in removing contaminants from complex shapes and delicate items. Common applications include cleaning jewelry, medical instruments, automotive parts, and electronic components. Each of these applications requires specific considerations regarding the size of the tank, frequency of the ultrasonic waves, and solution used. For instance, jewelry cleaning may require a lower frequency to avoid damaging delicate stones, while automotive parts might benefit from a higher frequency for thorough degreasing.

In addition to application-specific requirements, the volume and capacity of the ultrasonic cleaning tank must align with the items being cleaned. Medical facilities often need larger tanks that can accommodate multiple instruments, ensuring efficient sterilization without compromising cleanliness. Similarly, cleaning electronic components may necessitate a tank that allows for precise control of the cleaning conditions to avoid circuit board damage. Understanding these specific needs is crucial when selecting the right ultrasonic cleaning tank, as it directly impacts the efficiency and effectiveness of the cleaning process.