Leave Your Message

As the pharmaceutical industry evolves, so does the technology behind Pharmaceutical Grade Water Purifiers. Experts in the field emphasize the importance of high-quality water for manufacturing. Dr. Emma Caldwell, a recognized authority in pharmaceutical water treatment, once stated, "Purity of water is non-negotiable in drug production." This statement highlights the critical role of purification systems.

In 2026, innovative trends are transforming how we approach water purification. The integration of advanced filtration technologies and IoT capabilities is becoming commonplace. These innovations not only enhance efficiency but also ensure compliance with stringent regulations. Yet, challenges remain. Many facilities struggle to keep pace with rapid advancements.

Addressing these challenges is vital for companies aiming to maintain product integrity. The competition is fierce, and outdated systems can lead to costly mistakes. Continuous improvement is key. The future of Pharmaceutical Grade Water Purifiers hinges on adaptability and embracing new technologies. This is where industry leaders can make a real difference.

The landscape of pharmaceutical water purification is rapidly evolving. Emerging technologies offer exciting prospects for enhancing water quality. These innovations focus on efficiency and reliability. One notable advancement is the integration of smart sensors. These sensors monitor water quality in real-time, ensuring compliance with stringent regulations. They also provide critical data, making operations more efficient.

Membrane filtration continues to be a key area of innovation. New membrane materials promise higher throughput and better rejection rates of contaminants. However, these materials often require fine-tuning and testing before they can be widely implemented. This process can be time-consuming, posing challenges for manufacturers looking for quick solutions.

Additionally, UV disinfection methods are becoming more sophisticated. Advanced UV systems ensure thorough pathogen inactivation. Despite their effectiveness, some systems struggle with fouling, which can impact performance. Ongoing research aims to address these challenges, making these technologies more robust and user-friendly. The journey toward optimal pharmaceutical water purification is full of potential and hurdles alike.

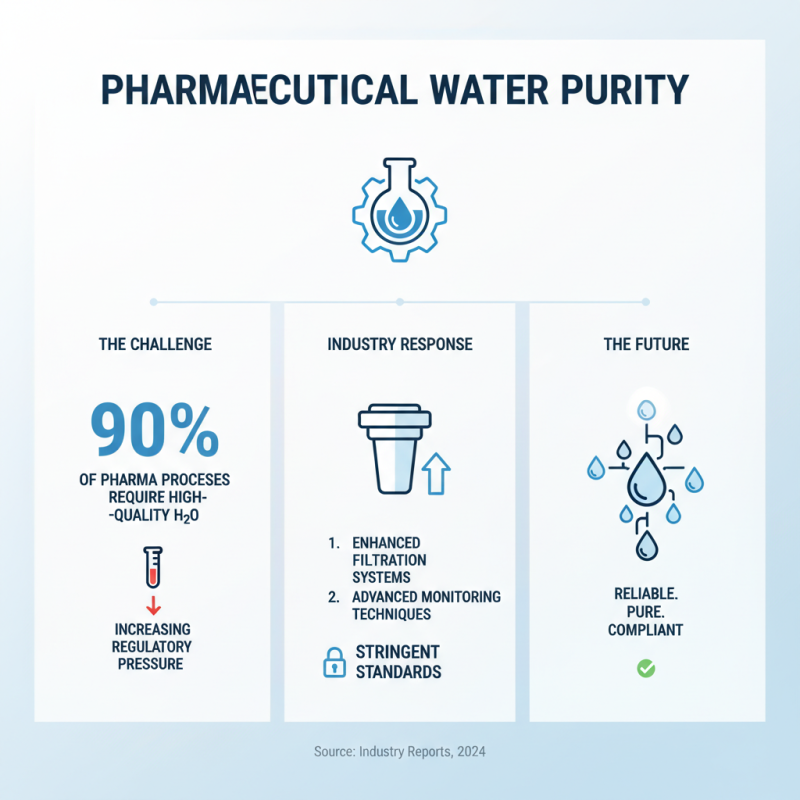

The pharmaceutical industry faces increasing pressure to ensure water purity. Recent reports indicate that 90% of pharmaceutical processes require high-quality water. Trends are emerging in water purification technologies, aiming to meet stringent industry standards. These include enhanced filtration systems and advanced monitoring techniques.

Membrane filtration is gaining traction. It offers effective removal of contaminants. A study found that 70% of companies are investing in membrane technologies. However, challenges remain in scaling these solutions. Balancing purification efficiency and operational costs is critical. Innovations like smart sensors are helping track water quality in real-time.

Despite advancements, there are still gaps in regulatory compliance. Many facilities struggle with outdated systems. A 2021 survey revealed that 40% of manufacturers face hurdles in meeting water quality regulations. Continuous improvement and investment are necessary. The path forward requires collaboration and innovation to address these challenges comprehensively.

Innovative filtration methods are reshaping the landscape of pharmaceutical grade water purification. Advanced technologies focus on enhancing water quality significantly. Technologies like reverse osmosis and nanofiltration are becoming more common. They provide unprecedented purity levels for critical applications. These methods help remove contaminants and pathogens effectively.

In recent years, there has been growing interest in integrated filtration systems. These systems combine multiple techniques for optimal results. With each technology contributing its strengths, we see improved overall efficiency. However, the complexity of these systems can lead to maintenance challenges. Regular checks and calibrations are necessary to ensure peak performance.

New materials are also emerging in filtration technology. Membranes made from advanced polymers show great promise. They offer higher flux rates and better chemical resistance. Yet, the durability of these materials needs further investigation. Some may degrade faster than expected, affecting long-term use. As we continue to innovate, evaluating these trade-offs is essential for advancing water purification processes.

Regulatory standards play a critical role in the development of pharmaceutical grade water purifiers. These standards ensure that the water used in the pharmaceutical industry meets rigorous safety and quality requirements. Compliance with regulations, such as those set by health authorities, is essential for manufacturers. These guidelines influence every aspect of water purification systems.

The evolving regulations introduce new challenges. Manufacturers must stay updated with the latest requirements. This often means adapting their technologies to meet stricter guidelines. For instance, recent regulations emphasize the need for advanced filtration methods. These innovations include better substances that can target impurities more effectively. Such changes require ongoing investment in research and development.

Moreover, the focus on sustainability is reshaping standards. Eco-friendly practices are becoming essential in water treatment processes. Companies are rethinking their approaches to waste management and energy consumption. While these advancements are promising, implementing them can be difficult. Organizations may face challenges in balancing compliance with efficiency. The quest for perfection continues, as each new regulation prompts reflection on processes and technologies.

| Trend/Innovation | Description | Regulatory Impact | Projected Market Growth (%) |

|---|---|---|---|

| Advanced Filtration Technologies | Integration of multi-stage filtration systems for improved purity. | Compliance with stringent FDA and EMA guidelines. | 15% |

| Smart Purification Systems | IoT-enabled systems for real-time monitoring and maintenance. | Adherence to data integrity regulations. | 20% |

| Eco-Friendly Solutions | Use of sustainable materials and energy-efficient processes. | Support for green initiatives in pharma regulations. | 10% |

| Modular Water Systems | Customizable modular systems for varying production needs. | Flexibility under current manufacturing regulations. | 12% |

| AI and Machine Learning Integration | AI-driven analytics for quality assurance. | Compliance with quality management standards. | 18% |

The trend toward sustainability in water purification is gaining momentum. Recent studies indicate that around 70% of companies are now prioritizing eco-friendly practices. They focus on reducing water waste and energy consumption. Advanced technologies are emerging to make purification processes more efficient.

Innovative solutions like membrane filtration and UV purification are leading the way. These methods consume less energy compared to traditional techniques. They also reduce the need for harmful chemicals. However, sustainability remains a challenge. Many facilities still depend on outdated systems. Upgrading infrastructure can be costly, leading to hesitation.

Research indicates that improved water quality can enhance public health. Clean water is vital for research and pharmaceutical production. Yet, there is a gap in accessibility to these technologies. Industry experts suggest a need for collaborative efforts to share knowledge and resources. Sustainable practices in water purification can reduce environmental impact while ensuring safety. Investing now will yield benefits for future generations.